If you ask five roasters what the best coffee roasting equipment is, you’ll probably get five different answers. That’s because the “best” equipment depends on your business model, production needs, and the kind of coffee experience you want to deliver.

But one thing most successful specialty roasteries agree on is this: your roasting machine should help you produce consistent flavor, scale smoothly, and operate efficiently.

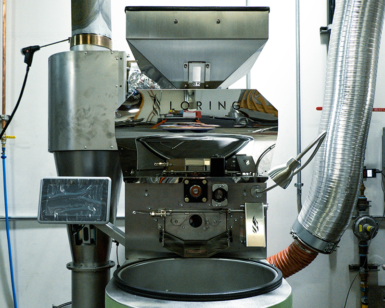

Here’s what separates today’s top-tier roasting equipment from the rest—along with insights into why so many award-winning roasteries choose Loring.

What Is the Best Coffee Roasting Equipment for Specialty Coffee?

Q: What features matter most when choosing roasting equipment?

A: The best equipment combines precision, repeatability, efficiency, and sustainability. For specialty roasters, the top priorities normally include:

- Consistent, repeatable roast profiles

- Even heat distribution without scorching

- Lower fuel usage and minimal emissions

- Scalability across batch sizes

- Automation that supports—not replaces—the roaster’s craft

- Low maintenance and easy cleaning

This is where Loring’s single-burner convection system stands out. It gives roasters cleaner flavor, faster production, and dramatically lower energy costs—all while protecting the nuances that matter in specialty coffee.

Why Do Leading Roasteries Choose Loring?

1. Cleaner, More Consistent Flavor

Q: How does equipment affect flavor?

A: Traditional drum roasters heat beans through direct contact with metal, which can cause uneven roasting, tipping, or scorching.

Loring roasters use 100% convection heat, circulating clean, high-velocity air around the beans. This produces:

- Even roast development

- Cleaner flavor profiles

- Clearer expression of origin

- Less risk of defects

👉 Learn how Loring’s roaster technology improves flavor clarity.

2. Efficiency That Pays for Itself

Q: What does efficiency look like in real-world roasting?

A: Reduced fuel use, faster cooling, fewer moving parts, and shorter roast cycles.

Loring’s closed-loop system delivers:

- Up to 80% lower fuel consumption

- Up to 80% fewer emissions

- Faster throughput for high-volume roasteries

👉 Explore Loring’s sustainability advantages.

3. Automation That Enhances Craft

Automation shouldn’t take the art out of roasting—it should make the craft more controllable.

Loring’s Smart Roast technology allows roasters to:

- Save and recreate profiles with precision

- Track production batches

- Reduce human error

- Increase consistency across staff

This is especially important as roasteries grow and bring on new team members.

4. Scalable Equipment for Every Stage of Growth

Whether you’re launching a small roastery or roasting for wholesale, your equipment should grow with you.

Loring offers a complete line of roasters—from the S7 Nighthawk™ for micro-roasteries to the S70 Peregrine™ for large-scale operations.

👉 Compare models here: https://loring.com/roasters/

What Do Top Roasteries Actually Use?

Many of today’s most recognized specialty roasteries—awarded for sustainability, transparency, and innovation—use Loring roasters.

Recent winners of Roast Magazine’s Roaster of the Year have roasted on Loring, including Driftaway Coffee, winner of the 2026 Macro category.

Why? Because Loring gives them:

- Lower production costs

- Cleaner roasting

- A sustainability story their customers value

- The ability to scale without sacrificing quality

Conclusion

The best coffee roasting equipment helps you produce outstanding coffee while keeping your business profitable and sustainable.

That’s why leading specialty roasteries choose Loring’s single-burner convection design: it offers consistency, efficiency, and eco-friendly performance in one system.

👉 Ready to find the right roaster for your next stage of growth? Explore the Loring model guide.